English

Jul 11, 2024

Film production is a dynamic industry that relies on cutting-edge technology to create high-quality products efficiently and effectively. Among the many components involved in film manufacturing, the blown film die head plays a critical role in shaping the final product.

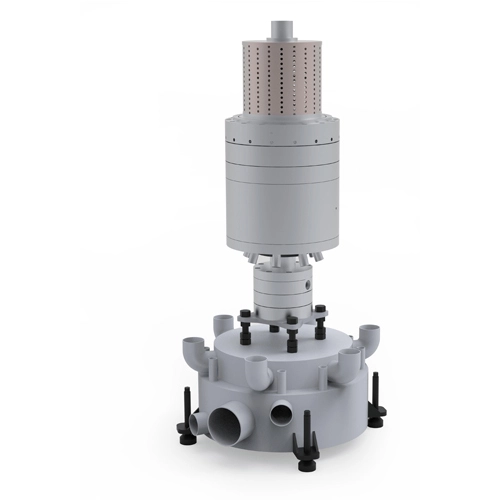

Blown film die head is a precision-engineered device used in the extrusion process to create plastic films of various thicknesses and properties. The die head is responsible for shaping the molten polymer into a hollow tube, which is then inflated to the desired size using air pressure. As the tube expands, it is cooled and flattened to form a flat film that can be wound onto rolls for further processing.

BOJING's blown film die heads are renowned for their precision engineering and exceptional performance. Each die head is meticulously designed and manufactured to meet the exacting standards of the film industry, ensuring consistent and reliable operation under demanding conditions. With advanced design features and high-quality materials, BOJING's die heads deliver superior film quality and production efficiency.

One of the key advantages of BOJING's blown film die heads is their versatility and customization options. Whether producing mono-layer or multi-layer films, BOJING offers a range of die head configurations to suit specific production requirements. From flat dies to spiral mandrel designs, each die head can be tailored to accommodate different resin types, film thicknesses, and output capacities, providing flexibility and adaptability for a variety of applications.

Cooling is a critical step in the blown film extrusion process, and BOJING's die heads are designed to optimize cooling efficiency and bubble stability. By incorporating advanced cooling technologies and precise flow control mechanisms, BOJING's die heads ensure uniform temperature distribution across the film bubble, minimizing variations in thickness and enhancing film quality. This results in smoother, more consistent films with improved optical properties and mechanical strength.

BOJING's blown film die heads are engineered for reliability and longevity, helping to minimize downtime and maintenance costs for film manufacturers. With robust construction and durable components, BOJING's die heads are built to withstand the rigors of continuous operation, reducing the need for frequent repairs or replacements. Additionally, BOJING offers comprehensive technical support and maintenance services to ensure optimal performance and maximum uptime for its customers.

Blown film die heads are essential components of the film extrusion process, and BOJING's innovative solutions set the standard for quality, performance, and reliability. With precision engineering, versatility, and advanced cooling technologies, BOJING's die heads offer film manufacturers the tools they need to produce high-quality films efficiently and cost-effectively. Whether producing packaging films, agricultural films, or industrial films, BOJING's blown film die heads deliver superior results, helping customers stay ahead in today's competitive marketplace.