English

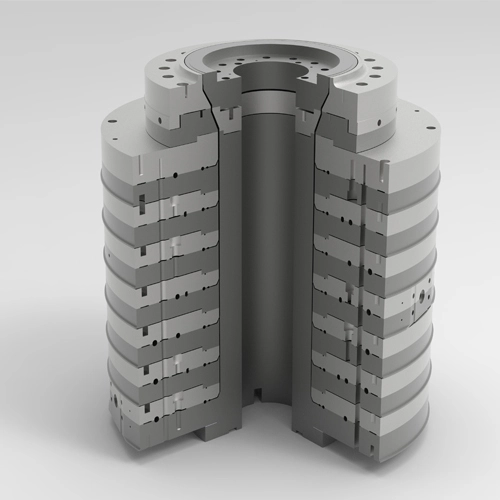

The IBC die head can effectively increase the production capacity of the product, and is a highly recommended choice for guests who want to increase the production volume of the film. In addition, the total plastic film extrusion production capacity of the product can be effectively increased through the combination of different design of wind rings.

Roundness, concentricity, perpendicularity

Perfect film thickness tolerance

High pressure output (according to customer demand)

Simple cleaning and maintenance

Fast refuelling and color change speed, reduce raw material consumption

Internal and external cooling systems

Appropriate pressure release

Provide suitable plastic retention time

The flow rate between channels is equal

Initial Inquiry

Technical Confirmation & Recommendations

Drawings

Manufacturing & In Process Quality Control

Final Quality Control

Packing & Shipping

Plastic film extrusion is a manufacturing process used to create thin, flexible plastic sheets. It involves heating plastic resin, forcing it through a die, cooling it, and winding it onto rolls.

Common types of plastic films include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and nylon. These films have various applications like packaging, agriculture, construction, and medical fields.

Polyethylene films are popular due to their versatility, durability, chemical resistance, and heat sealing properties. They are used in packaging, consumer goods, agriculture, and construction.

Plastic blown film extrusion is a manufacturing process used to create thin, tubular plastic films. Here's a breakdown of the process:

Resin Feeding: Plastic resin is fed into the extruder hopper.

Heating: The resin is heated to a molten state.

Extrusion: The molten plastic is forced through a circular die, forming a tubular parison.

Inflation: Air is blown into the parison, causing it to expand and form a bubble.

Cooling: The bubble is cooled to solidify the plastic.

Collapsing and Winding: The bubble is collapsed and wound onto a roll.

ARE YOU STILL NOT SURE WHICH TYPE OF DIE HEAD YOU WANT TO BUY?

PLEASE CONTACT US!

Tel:

E-mail:

Address:

NO.1, Yongning Road, Feiyun New District, Ruian City, Zhejiang