English

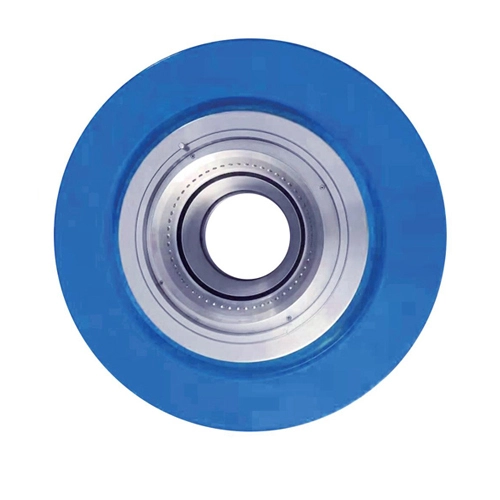

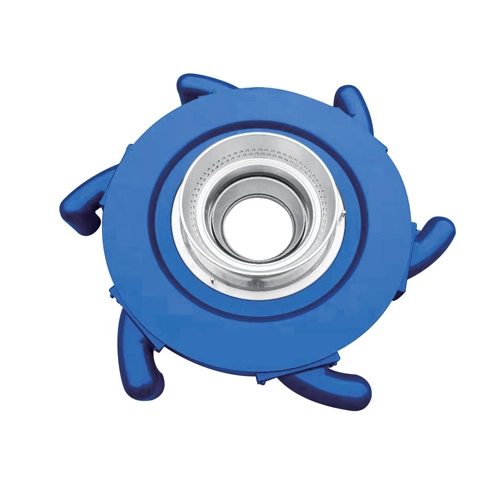

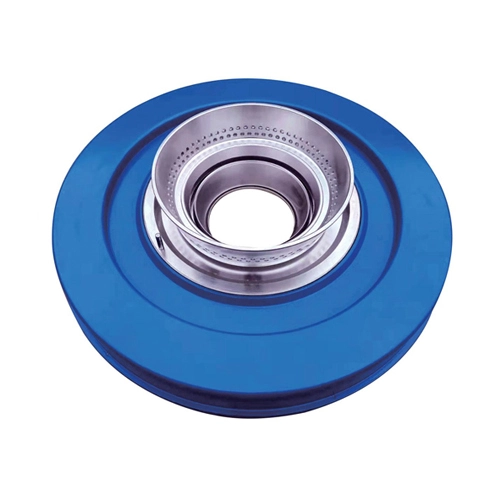

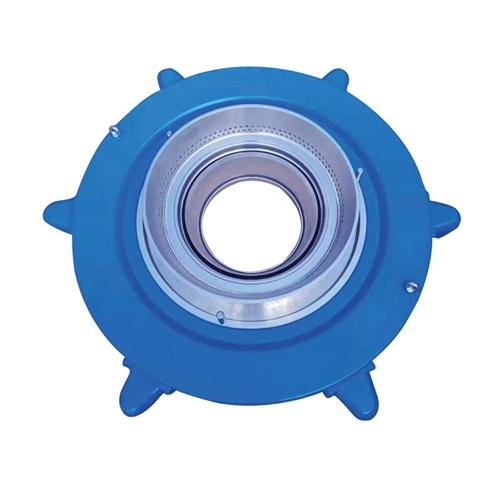

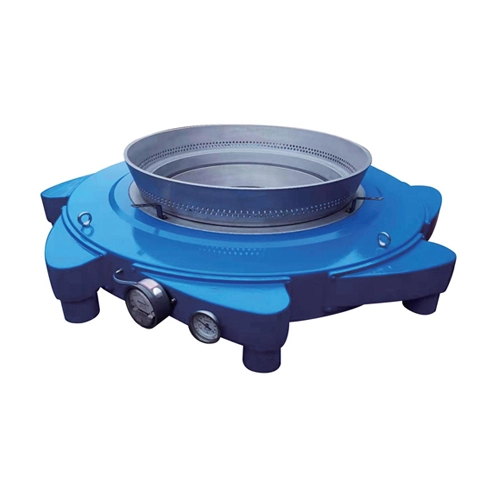

The high-pressure air ring is an essential element in the blown film extrusion process, engineered to deliver swift and effective cooling to the extruded polymer bubble. Its main role is to stabilize and cool the molten film as it emerges from the extrusion die, guaranteeing consistent thickness and superior film quality.

Multi-Lip Configurations: Modern high-pressure air rings often feature multi-lip designs, which provide multiple layers of cooling air. This ensures more uniform cooling and better control over the film bubble, resulting in higher quality films with consistent thickness and improved mechanical properties.

Automated Adjustments: Integration of smart control systems allows for real-time monitoring and automatic adjustments of airflow and pressure. This ensures optimal cooling conditions are maintained throughout the production process, reducing the need for manual intervention and minimizing the risk of defects.

Data Analytics: Advanced sensors and data analytics tools can monitor various parameters such as temperature, pressure, and airflow. This data can be used to optimize the cooling process, improve film quality, and increase production efficiency.

Efficient Heat Dissipation

Increased Production Speed

Enhanced Clarity and Strength

Optimized Airflow

Reduced Cooling Time

Precise Control

To make an air ring, we need to conduct preliminary treatment of aluminum alloy, foundry manufacturing, lathe processing, drilling, grinding, product assembly, painting (we can have a variety of colors to choose), and finally superior testing

ARE YOU STILL NOT SURE WHICH TYPE OF DIE HEAD YOU WANT TO BUY?

PLEASE CONTACT US!

Tel:

E-mail:

Address:

NO.1, Yongning Road, Feiyun New District, Ruian City, Zhejiang