English

The function of the blown film air ring is to cool the film bubble squeezed from the mold and blowing the molding, and the cooling medium is air. At the same time, the airflow also plays a certain role in supporting the membrane bubble. Efficient wind ring can significantly increase the output of the unit.

The membrane bubble formed by the membrane blowing machine is molten, which needs to be cooled quickly. Otherwise, there will be membrane bubble fall or adhesion in the winding, which will affect the normal production. In addition, the rapid cooling of the membrane bubble has greatly improved the mechanical properties and optical properties of the thin film products.

Cooling: Its primary role is to rapidly cool the molten polymer film as it exits the die head. This rapid cooling solidifies the film, giving it the necessary strength and rigidity.

Shape Control: The air ring directs a controlled stream of air onto the expanding bubble of molten polymer, helping to shape and stabilize it.

Film Thickness Control: By carefully adjusting the air flow and temperature, the air ring influences the film thickness and uniformity across the entire width.

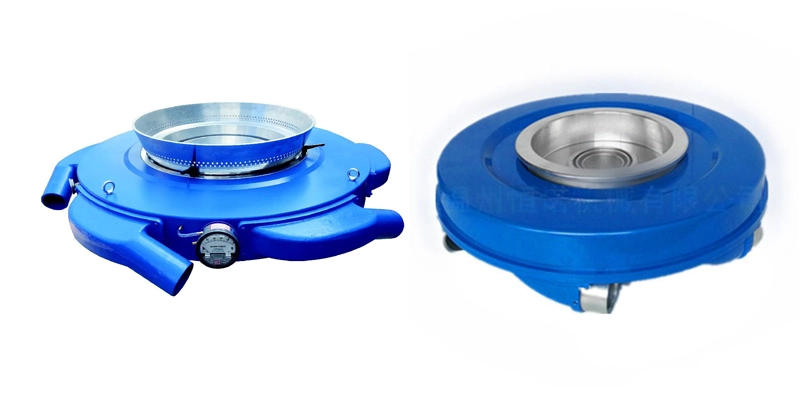

From the structure of the air cooling ring (air outlet) is divided into: air intake, air change main body, rotating body, upper and lower lips (outlet) several parts. There are an even number of air intakes, which are evenly distributed in the lower part or side of the air ring and connected with the fan air distribution bag through the air duct. The main body of the blown film air ring is a hollow shell with a labyrinth section, and the built-in guide blade plays the role of homogenizing air flow and establishing air pressure. Between the upper and lower lips is an outlet, and the air flow is blown out in a 360 degree manner. The mouth of the air cooler outlet is set at an Angle to control the Angle of contact between the air flow and the membrane vesicles. The upper lip is fixed on the rotating body and can be rotated up and down to adjust the size of the outlet.

A blown film air ring is an essential component in the blown film extrusion process, which is used to produce plastic films. Its primary role is to cool and stabilize the molten polymer as it is extruded through a circular die and inflated into a bubble.

Extrusion and Bubble Formation: The process starts with the extrusion of molten polymer through a circular die, forming a thin-walled tube. This tube is then inflated with air to create a bubble.

Positioning of the Air Ring: The air ring is strategically placed just above the die, encircling the bubble. It is designed to direct a controlled flow of air onto the molten polymer.

Air Flow and Cooling: The air ring has a series of air channels and nozzles that direct a uniform flow of air onto the bubble. This air flow cools the molten polymer rapidly, causing it to solidify into a film. The cooling process is critical because it determines the film’s final properties, such as thickness and clarity.

Stabilization of the Bubble: As the polymer cools, the air ring helps to stabilize the bubble, ensuring it maintains a consistent shape and thickness. This stabilization is crucial for producing a uniform film. The air ring achieves this by providing a balanced and even distribution of air around the bubble.

Adjustability for Optimization: Many air rings are adjustable, allowing operators to fine-tune the airflow to achieve the desired film properties. Adjustments can be made to the air pressure, flow rate, and distribution to optimize cooling and stabilization. This flexibility is important for accommodating different types of polymers and film specifications.

Dual-Lip Design (Optional): Some advanced air rings feature a dual-lip design, where two separate streams of air are directed at different points on the bubble. The primary lip provides initial cooling, while the secondary lip offers additional cooling and stabilization. This design enhances the efficiency and effectiveness of the cooling process.

Film Thickness Control: Air rings help to control the thickness of the blown film by regulating the air pressure and distribution. This is essential for producing films with consistent properties and desired thicknesses.

Film Bubble Stability: Air rings contribute to the stability of the blown film bubble, preventing it from collapsing or becoming uneven. This ensures a uniform and high-quality film.

Film Width Control: By adjusting the air flow and distribution, air rings can help to control the width of the blown film. This is important for producing films with specific dimensions.

Film Surface Quality: The design and operation of the air ring can influence the surface quality of the blown film. Well-designed air rings can help to minimize defects such as wrinkles, creases, and uneven surfaces.

Energy Efficiency: Efficient air ring designs can help to reduce energy consumption during the blown film extrusion process. This can lead to cost savings and improved environmental sustainability.

Versatility: Air rings are available in various designs and sizes, making them suitable for a wide range of blown film applications, from packaging films to specialty films.

1. The size of air volume: The air volume for high-pressure blown film air rings is generally higher to achieve the necessary cooling rates, while it is generally lower for low-pressure air rings, which focusing on precision rather than speed.

2. Wind pressure: High-pressure air cooling rings operate at higher air pressures, typically ranging from 0.5 to 2.0 bar (7 to 30 psi). Low-pressure air rings operate at lower air pressures, typically ranging from 0.1 to 0.5 bar (1.5 to 7 psi).

3. Applicable materials: The materials used in high pressure air rings need to withstand high pressures and provide efficient cooling, while low pressure air cooling rings need stable and uniform materials.

A compressor outlet is the point at which compressed air or gas exits a compressor. This outlet is typically connected to a system of pipes, hoses, or storage tanks that distribute the compressed air or gas to various applications. The compressor outlet is crucial for delivering the pressurized medium to tools, machinery, or processes that require it, ensuring efficient and effective operation.

I do. Can be specially customized, it is generally recommended that HDPE materials use low pressure wind ring, LDPE with high pressure wind ring.

Different process prices are naturally different, and if you want to cool faster, the price of products with higher output will naturally be higher.

The blown film air ring cools and stabilizes the molten polymer bubble in the blown film extrusion process. It ensures uniform film thickness, enhances mechanical and optical properties, and prevents defects. By providing controlled, even air distribution, it increases production efficiency and improves the overall quality of the plastic film.

ARE YOU STILL NOT SURE WHICH TYPE OF DIE HEAD YOU WANT TO BUY?

PLEASE CONTACT US!

Tel:

E-mail:

Address:

NO.1, Yongning Road, Feiyun New District, Ruian City, Zhejiang